.

Quality Inspection Services In Bangladesh

Quality is a major concern when importing products. Receiving defective products not only damages your supply chain but also sales. Asia Textile Inspections provides Quality Inspection and Factory audit services in Bangladesh. Quality concerns are one of the prime struggles. That importers face all over the world.

Bangladesh’s export industry is flourishing greatly. Resulting in the country becoming a direct competitor of China, especially in the Textile industry. This is why importers all over the world are considering moving their business from China to Bangladesh.

However, a word of caution is advised. As low costs often result in poor quality. It is important for you to strike a balance between costs and quality. Our working methodology distinguishes us from our competitors. The Following Product inspection Services are provided in Bangladesh;

- Pre-Production Inspection Service

- During Production Inspection Service (DUPRO)

- Initial Production Inspection Service

- Container Loading Inspection/Supervision

- Pre Shipment Inspection Service

- Manufacturing Audit

- Social Compliance Audit

If you have any questions or require a quick quote, please use the Live chat function or click here “Request a Quote”

Why should you use a factory audit or a product inspection when buying from Bangladesh?

As the world becomes increasingly integrated. It is essential for businesses to stay on top of their competition not only in terms of prices. But also, more importantly, the quality of the products.However, as businesses import from developing countries such as Bangladesh in hope of cutting costs there is always a fear.

This is where ATI comes to your service and helps you in verifying that the products you receive are not only meeting with your product specifications and requirements but also making sure that you exceed your customer’s expectations is essential if you wish to remain in business profitably in today’s intense competition.

Which service is the best choice for you? Read a detailed breakdown of our services below:

Pre-Production Quality Inspection

Pre-production inspection is one of the earlier steps of the whole inspection process. This inspection can be taken place either before the production phase or at the early stage of the final assembly.

What checklist required during a pre-production inspection?

Let’s take an overall look at the following most common elements that this pre-production inspection step covers:

- The Materials/Components:

With an aim to attract customers, suppliers usually offer cheap rates of raw materials and other goods. Cheap rates mean cheap and low-quality materials and the use of these low-quality products might be against your country’s laws.

To make sure that all of the materials used in your products comply with standards and come under your country laws, our inspection team members take product samples randomly and send them further to the laboratory for complete testing.

Our inspectors usually verify different properties of your products like color, weight, size, height, and others to make sure that your products are according to your requirements.

- A Prototype

When it comes to big-in-size products like beds, cupboards, and other items then sending a product sample to the laboratory for testing is not a possible inspection team. So, you can ask our inspection team member to go to the site and send you product photos in order to get verified by you.

- The Processes Of Mass Production

As we all know that we can’t go to the manufacturing site to check whether the supplier manufacturing our products according to our requirements or not. To do so, our inspection team monitors the whole production process of your product for verifying the product’s production according to your specifications.

During Production Quality Inspection

DUPRO is the inspection process that takes place during the production process covers the following scenarios:

- Shipments with a huge quantity of goods.

- The flow of production for in-sequence products.

- Inspection of shipments with tight on-time requirements.

- Repetition of processes if results of pre-production inspection phases were not up to expectations.

Our qualified inspection team will inspect the whole production block and check product inflow for finding out any possible flaws. This whole inspection usually takes place after 10-15% completion of the stock. Our team will offer their suggestions and expert opinions to re-suspect flaws of the pre-production phase in order to correct them.

We make sure that every inspection process becomes the part of the record so that’s why our inspectors will keep you updated with their comprehensive inspection report with photos. We have a worldwide network of qualified and trained inspectors that will be on their work after a few days of receiving your request.

At ATI, we not only inspect but also give you our expert opinions during all stages of production. Doing so, helps you to find out any possible divergences by your supplier against your contract.

Initial Production Quality Inspection

Initial Production Inspection known as IPI is the inspection step that is supposed to take place at the very beginning of the whole production process. The basic purpose of this inspection is to check whether raw materials used in your products do comply with your expectations or not.

Following are the main key factors that we test during this initial production inspection:

- Evaluation of the production capacity and equipment in the factory, providing the estimated cargo ready date to the client for reference.

- Evaluation of whole quality control system to make sure that factory quality measures do match your quality standards or not

- Analysis techniques for the production process to ensure that every quality control measure is up to your requirements.

- Monitoring both the quality and quantity of every material used in the manufacturing of your product. The basic purpose of performing this evaluation is to anticipate any further complications and inform the factory on time. Doing this will meet product specifications and the client’s requirements on time.

Pre-Shipment/Final Random Inspection

Pre-Shipment inspection is a step taken by businesses all over the world to ensure that the products they receive through shipment meet their requirements before leaving the supplier’s factory.

Following are the objectives of a pre-shipment inspection process:

- Checking the quantity and quality of the stock.

- Examine products for any mistakes.

- Present a detailed report of imports and billing.

It is always a good idea to have your shipment thoroughly inspected before it is shipping out to you. Not only does it save you significant costs, but it also saves you a ton of time and effort. Not to mention the poor image that builds in your customer’s mind. If you sell them products that are of poor quality or do not meet the specifications or requirements as promised by you.

If during a pre-shipment inspection, the product found to have defected then this defect can be fixed by the manufacturer before shipping to you. This activity saves you a lot of your money and time that you spend on repairing or exchanging products if you receive them with defects.

Hence, pre-shipment inspection plays a very important role in preventing users from any time or money loss.

Container Loading Inspection

Container loading is like a last but not least step of inspection that ensures that our team of qualified inspectors is inspecting the whole loading process before sending a shipment.

The inspectors present on-site ensure that your order is complete. And securely loading into the container before shipment.This inspection is the stage whereby your shipment can be checked. Doing this inspection will check your product requirements in terms of amount, variety, packaging, and other factors as well.

The quality inspection step is one of the last steps of the whole inspection process that takes place at the factory during loading onto the container. The inspection and monitoring process consists of condition evaluation to verify product details, loaded quantities, packaging details and thorough supervision of the whole container loading process.

Following are the important aspects that need to cover before shipping product to the client :

- Full record covering weather forecast, container’s arrival time, container details along with vehicle number.

- Complete inspection and checking of container to find out any breakage, inner moisture along with the type and smell test for each product.

- On-site individuals will seal the container with customs and ATI’s original seal.

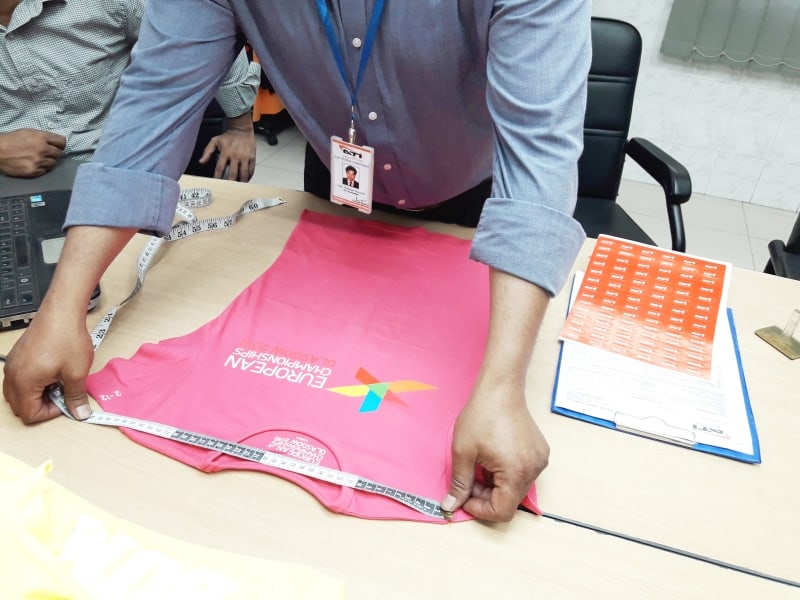

Our Quality Inspection Process in Bangladesh

Bangladesh is an emerging country, It is also a hub for textile manufacturers. Our product inspection services have a great impact on the quality on your imports. Following explains the entire inspection process is very transparent and the working methodology:

- Submit inquiry using “Request a Quote” on the top right corner and start communicating with one of our account managers.

- Share your Requirements

- We define the sample size after the confirmation of the requirements in case of inspections.

- We define the quality parameters as per AQL standards or as prescribed by the customer

- Defining number of major and minor defects or as prescribed by the customer

- Arrange inspection by coordinating with factory

- Have inspector on site within 24 hours and deliver the report in less than 24 hours