When it comes to underwear, comfort is key. And one of the most important factors that contribute to the comfort of underwear is the fabric. With so many different fabrics to choose from, it can be overwhelming to know which one is the best for your needs. That’s why it’s important to understand the benefits and qualities of each fabric before making a purchase.

Cotton is a popular fabric for underwear because of its breathability and softness. It’s a natural fiber that allows air to circulate, which can help prevent moisture buildup and keep you feeling cool and dry. Nylon and spandex are also common fabrics for underwear because of their stretchiness and ability to hold their shape. Mesh is another option that is lightweight and breathable, making it a good choice for active wear. However, it’s important to note that not all fabrics are created equal, and some may have negative effects on vaginal health.

Understanding Underwear Fabrics

Choosing the right underwear fabric is essential for comfort, durability, and maintaining good hygiene. There are many types of fabrics used in underwear, and each has its own unique characteristics and benefits. Here are some of the most common fabrics used in underwear:

Cotton

Cotton is the most popular fabric used in underwear. It is a natural fabric that is breathable, soft, and comfortable to wear. Cotton is also hypoallergenic, making it an excellent choice for people with sensitive skin. It is easy to care for and can be machine washed and dried.

Nylon

Nylon is a synthetic fabric that is commonly used in underwear. It is durable, lightweight, and has a smooth texture that feels great against the skin. Nylon is also moisture-wicking, which means it helps keep you dry and comfortable throughout the day.

Spandex

Spandex is a stretchy synthetic fabric that is often blended with other fabrics to add stretch and flexibility. It is commonly used in underwear to provide a snug and comfortable fit. Spandex is also durable and can withstand repeated washing and wearing.

Polyester

Polyester is a synthetic fabric that is commonly used in underwear. It is durable, lightweight, and has moisture-wicking properties that help keep you dry and comfortable. Polyester is also easy to care for and can be machine washed and dried.

Natural Fabrics

In addition to cotton, there are other natural fabrics used in underwear, such as bamboo, silk, and wool. These fabrics have their own unique characteristics and benefits. Bamboo is soft, breathable, and moisture-wicking, making it an excellent choice for underwear. Silk is soft, smooth, and luxurious, but it can be expensive and delicate. Wool is warm and moisture-wicking, making it a good choice for cold weather.

Overall, when choosing the right fabric for your underwear, consider factors such as comfort, durability, and hygiene. Natural fabrics like cotton, bamboo, silk, and wool are breathable and comfortable, while synthetic fabrics like nylon, spandex, and polyester are durable and moisture-wicking. Ultimately, the choice of fabric will depend on personal preference and individual needs.

Cotton Underwear

Cotton is a classic choice for women’s underwear and is a popular fabric for many reasons. It is lightweight, easy to clean, and made of natural fibers, providing a convenient and effortlessly-soft barrier between the skin and clothing. Additionally, cotton underwear is often crafted with vaginal health in mind, making it a great option for women who want to prioritize their health and comfort.

Organic cotton is a type of cotton that is grown without the use of synthetic fertilizers, pesticides, or other harmful chemicals. This makes it a popular choice for those who are looking for an eco-friendly and sustainable option. Pima cotton and Supima cotton are both high-quality varieties of cotton that are known for their softness, durability, and breathability. These types of cotton are often used in luxury underwear brands and are a great choice for those who want to invest in long-lasting, comfortable underwear.

Cotton Inc is a non-profit organization that promotes cotton as a versatile and sustainable fiber. They work with brands and manufacturers to develop new products and technologies that use cotton in innovative ways. Many underwear brands partner with Cotton Inc to ensure that their cotton underwear is of the highest quality and meets the needs of their customers.

Cotton-lined underwear is a popular choice for women who want to prioritize their vaginal health. Cotton is a breathable fabric that helps to prevent moisture buildup and reduces the risk of yeast infections and other vaginal irritations. Many women find that cotton-lined underwear is more comfortable and less irritating than synthetic fabrics.

Overall, cotton is a great choice for women’s underwear. It is a natural and breathable fabric that is easy to care for and comfortable to wear. Whether you prefer organic cotton, pima cotton, or Supima cotton, there are many options available that will meet your needs and preferences.

Synthetic Underwear Fabrics

Synthetic fabrics are popular choices for underwear as they offer a range of benefits such as durability, stretch, and moisture-wicking properties. Here are some of the most common synthetic fabrics used for underwear:

Polyester

Polyester is a popular synthetic fabric used for underwear due to its durability and moisture-wicking properties. It is also known for its ability to retain its shape even after multiple washes. However, some people may find polyester to be less breathable than other fabrics.

Nylon

Nylon is another popular synthetic fabric used for underwear. It is known for its strength, durability, and moisture-wicking properties. Nylon is also lightweight and dries quickly, making it a great choice for active individuals. However, like polyester, some people may find nylon to be less breathable.

Spandex/Elastane/Lycra

Spandex, elastane, and Lycra are synthetic fabrics known for their stretchiness. They are often blended with other fabrics to provide a comfortable and snug fit. These fabrics are also known for their ability to retain their shape, even after multiple washes. However, some people may find spandex blends to be less breathable than other fabrics.

Microfiber

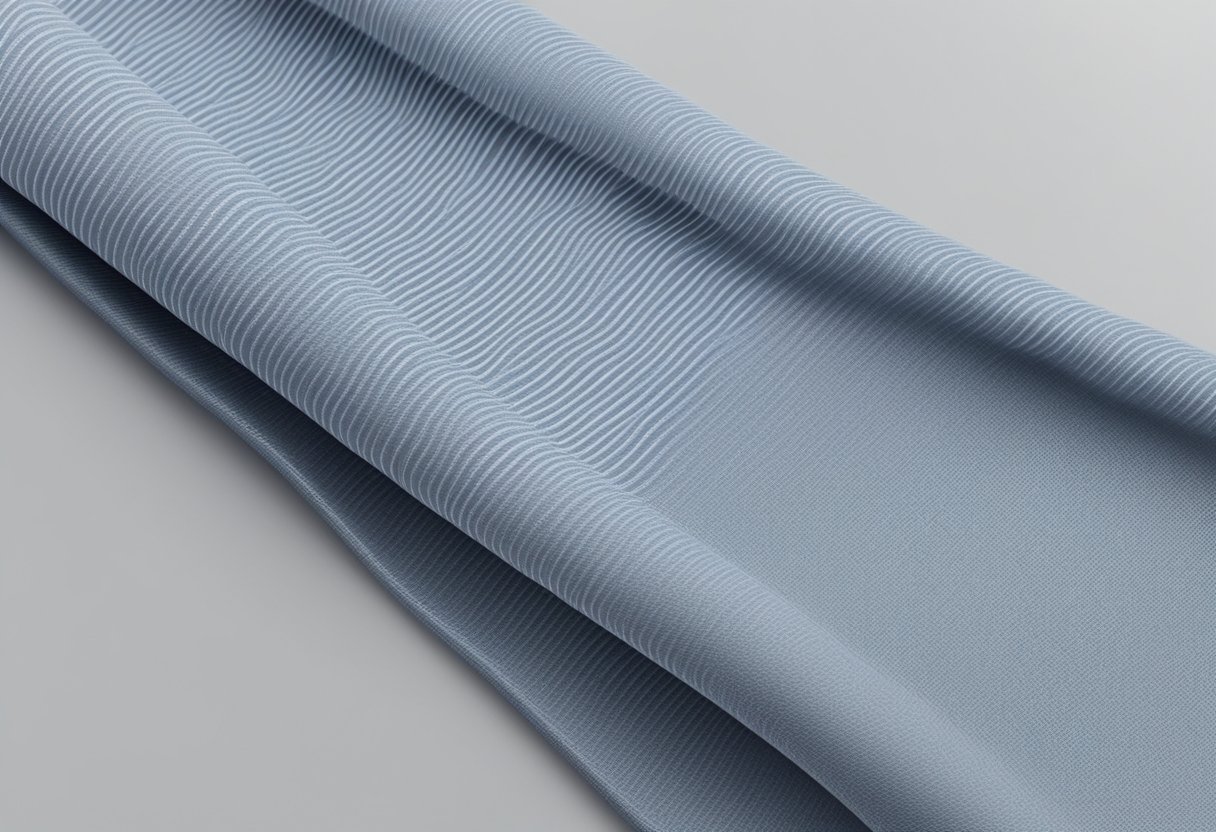

Microfiber is a synthetic fabric that is known for its softness and breathability. It is often used for underwear as it is lightweight, moisture-wicking, and quick-drying. Microfiber is also resistant to wrinkles and shrinking, making it a low-maintenance option.

Coolmax

Coolmax is a synthetic fabric that is designed to wick moisture away from the body, keeping the wearer cool and dry. It is often used for athletic wear and underwear as it is lightweight, breathable, and quick-drying. Coolmax is also known for its durability and ability to retain its shape.

Overall, synthetic fabrics offer a range of benefits for underwear, including durability, stretch, moisture-wicking properties, and breathability. When choosing synthetic underwear, it is important to consider factors such as the fabric’s breathability, moisture-wicking properties, and overall comfort.

Natural and Eco-Friendly Fabrics

For those who prioritize eco-friendliness, natural fibers like bamboo, silk, and organic cotton are great options for underwear. These fabrics are biodegradable, renewable, and free from synthetic chemicals and pesticides. They also tend to be more breathable and gentle on the skin.

Bamboo is a popular choice for eco-friendly underwear due to its sustainability and moisture-wicking properties. It requires less water and pesticides to grow compared to conventional cotton. Bamboo is also naturally antibacterial, making it a good option for those with sensitive skin.

Silk is another natural fabric that is luxurious and gentle on the skin. It is made from the fibers of the silkworm cocoon and is biodegradable. Silk is also naturally hypoallergenic and breathable, making it a great option for those with skin sensitivities.

Organic cotton is grown without the use of synthetic pesticides and fertilizers, making it a more sustainable option compared to conventional cotton. It is also biodegradable and soft to the touch. Organic cotton underwear is a great choice for those who want to reduce their environmental impact and avoid exposure to harmful chemicals.

In addition to these natural fibers, there are also eco-friendly options made from recycled materials such as polyester and nylon. These materials reduce waste and use fewer resources compared to virgin materials. However, it’s important to note that recycled synthetic materials may still shed microplastics during washing.

Overall, natural and eco-friendly fabrics are a great choice for those who want to prioritize sustainability and minimize their environmental impact.

Comfort and Breathability

When it comes to underwear, comfort and breathability are two of the most important factors to consider. The right fabric can make all the difference in how comfortable and breathable your underwear feels throughout the day.

Cotton is one of the most popular choices for underwear fabric because it is highly comfortable and breathable. It provides amazing softness and breathability, making it perfect for all skin types and every weather condition. Cotton is also skin-friendly, which means it is less likely to cause irritation or chafing.

Another great option for breathable underwear is bamboo viscose fiber. This material is soft, lightweight, and highly breathable. It is also hypoallergenic, which makes it a great choice for those with sensitive skin. Bamboo viscose fiber is also moisture-wicking, which means it can help keep you dry and comfortable throughout the day.

For optimum comfort, Supima cotton is an excellent choice. This premium cotton is made from the longest and finest fibers, which makes it incredibly soft and durable. It is also highly breathable, which means it can help keep you cool and comfortable all day long.

In addition to the fabric, the design of the underwear can also affect its comfort and breathability. Look for underwear with a breathable and moisture-wicking waistband, as well as a design that allows for plenty of airflow. This can help keep you cool and comfortable, even on the hottest days.

Overall, choosing a comfortable and breathable fabric is key to finding the perfect pair of underwear. Whether you prefer cotton, bamboo viscose fiber, or Supima cotton, there are plenty of options available to help you stay cool and comfortable all day long.

Durability and Maintenance

When it comes to choosing the best fabric for underwear, durability and maintenance are crucial factors to consider. Underwear is an essential item in everyone’s wardrobe, and it is essential to choose a fabric that can withstand daily wear and tear without losing its shape or elasticity.

Cotton is a popular choice for underwear due to its durability and ease of care. It can withstand multiple washes without losing its shape, making it a great option for everyday wear. However, it is essential to avoid using bleach or fabric softeners when washing cotton underwear as they can weaken the fabric and cause it to deteriorate faster.

Synthetic fabrics such as polyester and nylon are also durable and can withstand frequent washing. They are also quick-drying, making them ideal for active lifestyles. However, they are not as breathable as natural fabrics, which can lead to discomfort and irritation.

Modal is a newer fabric that is becoming increasingly popular for underwear due to its durability and softness. It is made from beech tree pulp and is more resistant to shrinkage and fading than cotton. It is also easy to care for and can withstand machine washing.

Silk is a luxurious fabric that is incredibly soft and comfortable to wear. However, it is not as durable as other fabrics and requires special care when washing. It is best to hand wash silk underwear or use a delicate cycle on the washing machine to avoid damaging the fabric.

In summary, when choosing the best fabric for underwear, it is essential to consider durability and maintenance. Cotton and synthetic fabrics are durable and easy to care for, while modal and silk offer superior softness and comfort. Regardless of the fabric chosen, it is important to follow the care instructions to ensure the underwear lasts as long as possible.

Underwear for Active Lifestyles

For those with active lifestyles, it is important to choose underwear that provides support and sweat control. Polyester blends, especially those with moisture-wicking capabilities, offer the best combination of support and sweat control for athletics and very active lifestyles. These fabrics are designed to wick moisture away from the skin and keep the wearer dry and comfortable.

When buying underwear for active lifestyles, it is important to look for stretchy fabrics that are lightweight, breathable, and moisture-wicking. Annette Dale-Kramek, activewear designer and founder of Ancient Language 97, recommends looking for fabric that wicks moisture away from the body, so moisture does not accumulate in the crotch area. This is important for both comfort and hygiene.

In addition to moisture-wicking properties, it is also important to choose underwear that stays in place during physical activity. Underwear with a snug fit and elastic waistband can help keep everything in place and prevent uncomfortable shifting and bunching.

For those who enjoy sports or working out, it is important to choose underwear that provides support and stays dry. Moisture-wicking fabrics can help prevent chafing and irritation, while providing the necessary support for physical activity. Some brands even offer underwear specifically designed for sports, with features such as compression and ventilation.

Overall, when choosing underwear for active lifestyles, it is important to prioritize stretch, moisture-wicking, and support. With the right fabric and fit, underwear can help keep the wearer comfortable and dry during even the most intense physical activity.

Underwear for Health and Hygiene

When it comes to choosing the right underwear, health and hygiene should be a top priority. Wearing the wrong type of underwear can lead to a variety of issues, including infections, irritation, and other vaginal health issues. Therefore, it is important to choose underwear that is comfortable, hypoallergenic, and promotes good vaginal health.

One of the most important factors to consider when choosing underwear is the fabric. Cotton is often recommended by gynecologists and health experts as the best fabric for underwear. Cotton is a natural, breathable fabric that helps to absorb moisture and prevent the growth of bacteria and yeast. This can help to reduce the risk of vaginal infections and other health issues.

Other fabrics that are recommended for underwear include bamboo, modal, and microfiber. These fabrics are also breathable and moisture-wicking, which can help to prevent irritation and other issues. However, it is important to choose high-quality fabrics that are hypoallergenic and free from harsh chemicals and dyes.

In addition to the fabric, the style of underwear can also impact vaginal health. Tight-fitting underwear, such as thongs, can increase the risk of vaginal irritation and infections. Therefore, it is important to choose underwear that fits well and provides adequate coverage and support.

Overall, choosing the right underwear for health and hygiene is essential for maintaining good vaginal health. By choosing breathable, hypoallergenic fabrics and avoiding tight-fitting styles, individuals can reduce their risk of infections, irritation, and other vaginal health issues.

Underwear Styles and Sizing

When it comes to women’s underwear, there are a variety of styles and sizes available. The right style of underwear can help you feel comfortable and confident all day long. However, choosing the wrong size or style can lead to discomfort and irritation.

One popular style of underwear is briefs. Briefs are a traditional style that offers plenty of support and coverage. They come in a range of sizes and materials, including cotton, mesh, and modal. For those who prefer a more minimalistic style, thongs are a great option. Thongs provide minimal coverage and are perfect for wearing under tight-fitting clothing.

Boxer briefs are another popular style of women’s underwear. They offer more coverage than traditional briefs and are perfect for those who prefer a looser, more relaxed fit. Plus size underwear is also available for those who need a little extra room.

When it comes to sizing, it’s important to choose the right size for maximum comfort and support. One sign that your underwear doesn’t fit is if you notice skin bulges around your hips or love handles. If this occurs, trying the next size up or switching to a style that provides more coverage and support may be necessary. Restricted leg movement is another sign that your underwear is too small.

Period panties are another popular style of women’s underwear. They are designed to provide extra protection during menstruation and come in a variety of styles and sizes. Some period panties even come with built-in absorbent material to prevent leaks.

Overall, choosing the right style and size of women’s underwear is essential for maximum comfort and support. With a variety of styles and sizes available, there is sure to be an option for every woman’s needs.

Specialty Underwear Fabrics

In addition to the standard fabrics like cotton and polyester, there are several specialty fabrics that are used for making underwear. These fabrics are designed to cater to specific needs, such as breathability, moisture-wicking, and comfort. Here are some of the most popular specialty fabrics used in underwear:

PUL (Polyurethane Laminate)

PUL is a waterproof and breathable fabric that is often used in cloth diapers. It is made by laminating a thin layer of polyurethane film to a fabric. PUL is a great choice for underwear for women who experience light bladder leakage or menstrual spotting. It can also be used as a barrier for people who suffer from excessive sweating.

Lightweight Fabrics

Lightweight fabrics like microfiber and mesh are great for underwear because they are breathable and moisture-wicking. Microfiber is a synthetic fabric that is soft, lightweight, and quick-drying. Mesh is a breathable fabric that is ideal for hot and humid climates.

Lounging Fabrics

For lounging, softer fabrics like micro modal and jersey knit are a great choice. Micro modal is a type of rayon that is made from beech tree pulp. It is known for its softness and breathability. Jersey knit is a lightweight and stretchy fabric that is ideal for lounging.

Long Underwear Fabrics

Long underwear fabrics like merino wool and silk are great for keeping warm in cold weather. Merino wool is a natural fabric that is known for its warmth, breathability, and moisture-wicking properties. Silk is a lightweight and luxurious fabric that is ideal for layering.

Elastics

Elastics are an important component of underwear. They are typically made from a blend of spandex and nylon. These materials provide stretch and support, ensuring that the underwear stays in place. Some brands use wider elastics to prevent digging into the skin.

Date Night Fabrics

For special occasions, lace and silk are popular choices for underwear. Lace is a delicate fabric that is known for its feminine and romantic look. Silk is a luxurious fabric that feels soft and silky against the skin. Both fabrics are breathable and lightweight, making them ideal for date night.

Boyshorts

Boyshorts are a type of underwear that provides more coverage than traditional panties. They are typically made from a blend of cotton, spandex, and nylon. This combination of materials provides comfort, stretch, and support. Boyshorts are a great choice for women who want more coverage or who want to avoid panty lines.

Choosing Underwear for Men and Women

When it comes to choosing the best fabric for underwear, both men and women have a wide range of options to choose from. The choice of fabric can have a significant impact on comfort, breathability, and overall quality. Here are a few things to consider when selecting the right underwear:

Fabric Types

For men’s underwear, cotton is a popular choice due to its breathability and softness. However, other fabrics such as Micro Modal, Bamboo Rayon, Nylon/Spandex blends, Silk, and Cotton/Modal blends are also gaining popularity. Each fabric has its unique properties, and it’s essential to choose one that suits your needs.

For women’s underwear, cotton is still a popular choice, but other fabrics like Modal, Nylon, Polyester, and Microfiber are also gaining popularity. Women’s underwear also comes in a wide range of styles, including thongs, briefs, boy shorts, and more.

Colors and Patterns

Underwear comes in a wide range of colors and patterns, and it’s essential to choose a style that makes you feel confident and comfortable. While some people prefer plain colors, others prefer bold patterns or prints. It’s all about personal preference.

Confidence

Wearing the right underwear can make you feel confident and comfortable. It’s essential to choose underwear that fits well and makes you feel good about yourself. Confidence is key, and the right underwear can help you achieve that.

In summary, choosing the right fabric for underwear is essential for both men and women. It’s important to consider the fabric types, colors, patterns, and how it makes you feel. By doing so, you can find the perfect pair of underwear that suits your needs and makes you feel confident and comfortable.