Quality assurance and quality control are two fundamental parts of the inspection process. By most people, these terms are wrongly used because they are interrelated areas of quality management.

Focus On Incoming Quality Concerns To Avoid Huge Losses

Up until the time that your production starts, incoming quality control (IQC) are the method of inspecting the quality of materials and parts used to make a product. You may inspect for consistency even before performing a first product inspection or an output inspection with the incoming inspection. This may deem incredibly important as a measure to prevent huge losses in the later stages of production, which may be aptly identified and subverted by carrying out an efficient incoming quality concern (IQC).

Which Type Of Quality Audit Is Best For Your Supplier?

Your supply ultimately determines the quality of products that you market to your customers. In essence, it would not be untrue to say that your supplier is wholly responsible for the reputation of your brand in the market- a good supplier can send your sales and profits rocketing to the sky (So deciding which type of quality audit is best for supplier is important) , whereas a bad one can do just the opposite, send you downhill not in your balance sheets but also in the eyes and minds of your customers.

CONTINUE READINGIs Your Supplier’s Quality Manual Taking Care Of Your Product Requirements?

Think of it this way. If you do not convey your expectations or requirements to someone. How will they know what you want them to do? This is very relevant when it comes to product quality and its inspection. Because without relevant and key information provided by you. The factory staff or your own product inspection team will be confused. As to what exactly you require your products to be like.

CONTINUE READINGWhy Supplier Audit Program Is A Must Have For Fashion Retailers Before CNY?

As a fashion retailer, you may have noticed that not only is the industry becoming more and more competitive. With new brands launching every other day in terms of audit program.

But also that the consumers are becoming highly demanding; they expect their products to be of high quality, free of any kinds of defects. But also delivered to them as quickly as possible. A rather complex task to achieve while keeping costs low but profitability high.

CONTINUE READINGA Beginner’s Guide to Quality Control in 4 Simple Steps

The trend of outsourcing production to another country is increasing day by day. Countries in Asia, particularly China, have seen immense growth in their industry as a result of importers from countries like the United States setting up their manufacturing units in these countries to significantly cut down costs.

CONTINUE READINGAcceptable Quality Limit | AQL Calculator – Sampling Table

Updated: 19 November 2021

The Meaning of AQL

Literally speaking, AQL standards for Acceptable Quality Limit: this means the worst quality that is tolerable or acceptable in a given sample of products according to the ISO 2859-1. This is basically the maximum amount of goods that an inspection team or buyer would accept that are of sub-standard quality.

Quality Inspection Using ISO 2859-1 and ANSI/ASQ Z1.4

Updated: 20 November 2021

The concepts of ANSI ASQ Z1.4 AQL might probably seem complicated to some, but there must be others who have some idea of what they refer to and what it is all about. We have done some extensive research for our user’s ease. So they have to go anywhere else searching for the correct information. In case you are one of such people, then you have landed on the right platform.

This article will let you know all the relevant things related to this topic and the significant differences between them. By the end of this article, we hope you will have a firm knowledge of the topic. At least the blur lines between these concepts will be cleared. Please read this information until the end without skipping anything to understand better these terms and what they imply.

There are attribute sampling plans that are primarily utilized to examine the productiveness of an item, product, or method to decide the compliance rate with already existing criteria. This practice is widespread in pharmaceutics to adopt American National Standards Institute (ANSI)/American Society for Quality (ASQ) Z1.4-2008. Sampling Procedures and Tables for Inspection by Attributes for inspection of product’s or item’s flaws.

This method gives the best instructions on how it is supposed to be implemented; however, it is mainly considered or perceived wrong. In this regard, the usual mistakes contain, but are not restricted to, the selection of wrong sampling size, choice of incorrect acceptance criteria, or attribute plan utilized for variable data, etc.

What is ANSI?

American National Standards or ANSI is known as a voluntary consensus standard that agrees with the ANSI essential requirements. Its primary mission is to increase both the universal productivity of American business and quality of life by encouraging and providing open consensus standards and conformity assessment systems and defending their unification.

This Institute holds within the diverse interests of more than 270,000 organizations, firms, and 30 million experts worldwide. The primary purpose of creating ANSI is to ensure that the development of American National Standards is a good and receptive way that is best to all directly and considerably affected parties.

The major aim of ANSI is to use U.S. standards at a worldwide level to promote American policy and technical positions in global and regional standards firms. Encourage them to adopt international standards as national standards where they fulfill the requirements of the user community.

What is ASQ?

ASQ is the American Society for Quality that was previously known as the American Society for Quality Control. It was based upon the work related to quality experts that have more than 80,000 members. It is created to offer better skills, professional networks, equipment, and methods to assist the best services to members, provide the finest products, and industries.

They are best at giving the ultimate training, certifications, and knowledge to members worldwide. It is a global organization that has its members in more than 130 countries. It is based on the communities that guide its members to connect with other quality professionals and experts and help them develop their knowledge and careers.

Here tools are being made, and resources are provided for the sake of necessary assistance to help member leaders have the finest opportunities. The primary aim is to empower people and communities of the world to gain excellence via quality.

What are Z1.4 and Z1.9 Standards?

The ANSI ASQ z1 4 standard is for future inspection of attribute characteristics. If the measurement is a variable measurement, it is suitable to utilize ANSI/ASQ Z1.9. Both ANSI ASQ z1 4 and ANSI ASQ z1 9 plans are indexed by AQL. But they have a different sample size based on the safety level that companies are looking to deal with.

It is a valid sampling system that is utilized with switching rules on a current stream of many for the sake of Acceptance Quality Limit (AQL) specified. It gives planned, average, and controlled decisions to be implemented for attributes inspection for percent nonconforming or nonconformities on the terms of every 100 units.

In the AQL table of Z 1. 9 is an acceptance of a sampling system that is utilized on a current stream by many for Acceptance Quality Limit (AQL). It gives strict, balanced, and controlled plans that are being used on measurements that are most shared. Here variation will be measured through different criteria, including sample range or sample standard deviation. It is applied based on the fact that the normality of the measurements is verified.

Using ISO 2859-1 and ANSI/ASQ Z1.4

As a buyer, you want to take every measure possible in order to ensure that you receive goods of adequate quality, in line with the specifications that you asked for. Although there is perhaps an endless list of methods you can employ to verify the quality of these products, this article presents an overview of some of the most effective options that you have, as a buyer, to gauge the quality of the goods through the findings presented to you after inspection.

One thing’s for sure, hardly any business checks each and every good produced during inspection– unless, of course, the goods produced are very less in number. It has been established that testing a ‘statistically significant’ number of goods as a sample can quite adequately represent the quality of the entire shipment.

For most businesses, Inspection level 2 is appropriate under normal conditions. However, certain circumstances may arise where the inspection team would fight it best to alter the sample size, either by reducing or increasing it.

It is thus established that you do not need to check each and every product to ensure quality standards in your manufacturing process; the next question that arises as to how many products to actually inspect, and why is there a need for different inspection levels?

One of the foremost, and perhaps obvious, principles associated with carrying out effective quality control is that the sample size increases with the number of goods ordered. Makes sense, right?

But, does this imply that the sample size is directly and solely linked to the number of goods ordered? Unfortunately, it’s not that simple. When deciding upon the optimal number of products to include in your inspection sample, it is important to keep the surrounding circumstances in mind, such as the previous history of the manufacturer.

Naturally, if the manufacturer has been lately producing a high number of sub-standard products, then you would wish to increase the number of products included in the sample. Similarly, if you find that there have been minimal cases of quality lapses over the years, perhaps you would feel that a smaller sample size would suffice.

Another significant factor that determines whether you would modify your sample size is the nature of the inspection. There are certain goods that only be tested through their usage or destruction, such fireworks can only be tested when they are used which results in the wastage and destruction of the product. In such circumstances, you would want to shorten your sample size.

For the reasons given above, and many more, a series of levels are proposed by MIL-STD 105 E (the widely used standard for quality control in the form of acceptance sampling). It is important to note that it has been formally replaced by different commercial standards such as ISO 2859-1, ANSI/ASQ Z1.4, etc.

Ultimately, it is the buyer’s decision to inform the inspection team about how many goods to inspect, or the inspection level. Keep in mind, that as you increase the number of goods in your sample, the surer you will be regarding the results of your inspection.

However, you would also simultaneously increase costs for yourself in terms of more manpower employed to inspect the sample, time, as well as money spent. It is thereby important to strike a balance between the two extremes according to your businesses’ needs.

Now, What are the 3 ‘General’ Inspection Levels that we’ve been talking about in this article?

Let’s take a look:

Level I

This level requires the least amount of goods in the sample for inspection. There may be several reasons why you would wish to limit the number of goods inspected, such as saving on cost and time.

To decide upon this level it is important to ask yourself the following questions:

- Has this supplier passed most previous inspections?

- Do you feel confident in the quality of their products?

- Do you have trust in the supplier’s abilities to produce good-quality products?

If the answer to these three questions is yes, then you may go ahead with this level. But remember that it comes with the most risk as well.

Level ll

This is the ‘default level’ used by most buyers and suppliers.

Level lll

For this Level Again, As Yourself These Three(3) Questions Once More:

- Has this supplier passed most previous inspections?

- Do you feel confident in the quality of their products?

- Do you have trust in the supplier’s abilities to produce good-quality products?

This time, if the answer for all of the above questions is a no, then you need to opt for this level. It is also common for very high-value goods in which you cannot afford even the slightest bit of slack in quality.

These inspection levels are applicable where only a few samples can be inspected or tested, such as in the case of destruction of the product during use, or where inspecting all the products takes up too much time.

Conclusion

We hope that users have a sufficient idea of the AQL table and the related terms such as ANSI z1 4, ANSI, ASQ z1.4. There is no doubt that for the sake of a successful quality inspection all these measures should be kept in mind so companies can do the task of quality control in the best way possible. Customers would be able to get the best of the best product in the end result. Keep in mind these sampling standards and use them wherever you think they are necessary. Let us know if you have any more questions. We would love to be of your assistance.

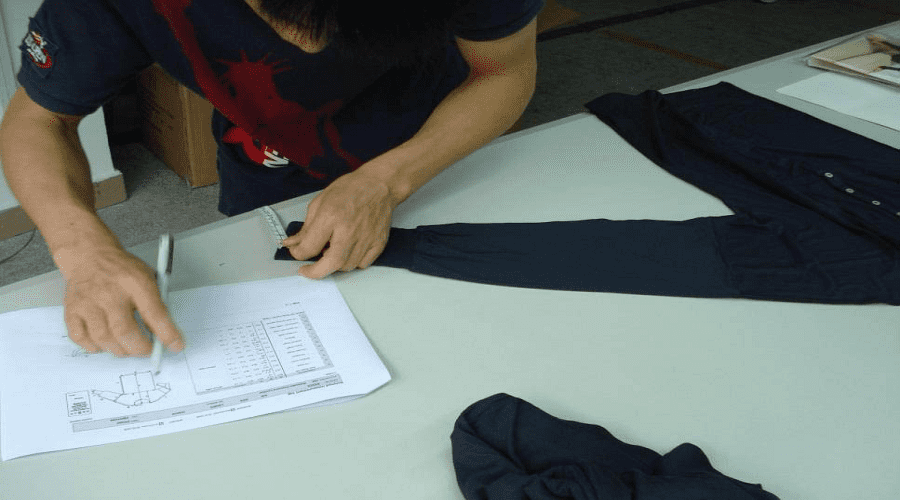

3 Ways To Ensure Quality Standards In Garments

It would not be wrong to say that quality is the backbone of any business; without quality products and services, especially in highly competitive markets that businesses operate in these days, any firm is unlikely to survive. This holds even more important for garments, where quality is difficult to nail given the labor-intensive nature of the product. Unlike large scale machine-manufactured products that can be made in large amounts with the exact same specifications for each unit, garments are stitched by hand and therefore are always subject to the risk of inconsistency between consecutive products and unsatisfactory quality.

CONTINUE READING3 Reasons Why You Don’t Want To Forgo Quality Inspection As An Importer

Quality is one aspect of a business’s products that consumers are most difficult to compromise on. Perhaps a business can get away with a sudden increase in price if consumers feel that the products are worth the money; they might even be given the margin of late deliveries if the customers demand that product is too high. However, the underlying idea is the quality which is an aspect that cannot be compromised upon.

CONTINUE READING